WR series assembled thermocouple

Product description:

The WR series assembly thermocouples are used as sensors for measuring temperature and are usually used in conjunction with display instruments, recording instruments, and electronic regulators. The liquid, steam and gas medium, as well as the surface temperature of the solid can be measured directly at various temperatures in 0~1800 degrees centigrade.

Working principle

The WR series assembly thermocouple consists of two different conductor materials. When there is a temperature difference between the measuring end and the reference end, the thermal potential is generated, and the work instrument shows the temperature corresponding to the thermal potential.

Product execution standards

IEC584, GB/T18404-2001, GB/T16839-1997, JB/T5518-1991, JB/T92389-1999 and so on

Measuring range and tolerance

Thermocouple class

Code number

Graduation number

Measuring range

Tolerance

30- platinum rhodium 6

WRR

B

Optional within 0~1800 centigrade range

+ 1.5 DEG C or + 0.25%t

10- platinum rhodium

WRP

S

Optional within 0~1600 centigrade range

+ 1.5 DEG C or + 0.25%t

Nickel chromium nickel silicon

WRN

K

Optional within 0~1300 centigrade range

+ 2.5 DEG C or + 0.75%t

Nickel chromium copper nickel

WRE

E

Optional within 0~800 centigrade range

+ 2.5 DEG C or + 0.75%t

Thermal response time of WR series assembled thermocouple

When a step change in temperature occurs, the output of a thermocouple or thermal resistance changes to the time required for 50% of the step change, called the thermal response time. Represented by tau 0.5.

Nominal pressure

Generally refers to the operating temperature, the protection of the tube can withstand the static external pressure is not broken. In fact, it is not only related to the tube material, diameter and wall thickness, but also to the structure, installation method, depth of installation and the flow velocity and type of the medium to be measured.

Minimum insertion depth of WR series assembled thermocouples

The ceramic protection tube shall be no less than 10~15 times the diameter of the protective tube; the metal and alloy protective tube shall be 15~20 times larger than the diameter of the protecting tube.

Normal temperature insulation resistance

The test voltage of insulation resistance at normal temperature is DC 500 + 50V. The atmospheric conditions for measuring insulation resistance at normal temperature are: temperature 15~35 DEG C, relative humidity 45%RH, atmospheric pressure 86 ~ 106kPa. Thermocouple placed under this condition shall be no less than 2 hours.

A. for a thermocouple with a length of more than 1 meters, the product of its room temperature insulation resistance and its length shall be no less than 100M Omega M. Rr: L = 100M m L = Omega 1m type: Rr thermocouple temperature insulation resistance value, M.

L - thermocouple length, M

B. for thermocouples whose length is equal to or less than 1m, its ambient insulation resistance shall be no less than 100M ohms.

Upper limit temperature insulation resistance

The upper temperature and insulation resistance value of thermocouple shall not be less than that specified in the following table:

Upper limit temperature Tm (DEG C)

The test temperature is t (DEG C)

The resistance value is M

100 < TM < 300

T= TM

Ten

300 < TM < 500

T= TM

Two

500 < TM < 850

T= TM

Zero point five

850 < TM < 1000

T= TM

Zero point zero eight

1000 < TM < 1300

T= TM

Zero point zero two

TM = 1300

T=1300

Zero point zero two

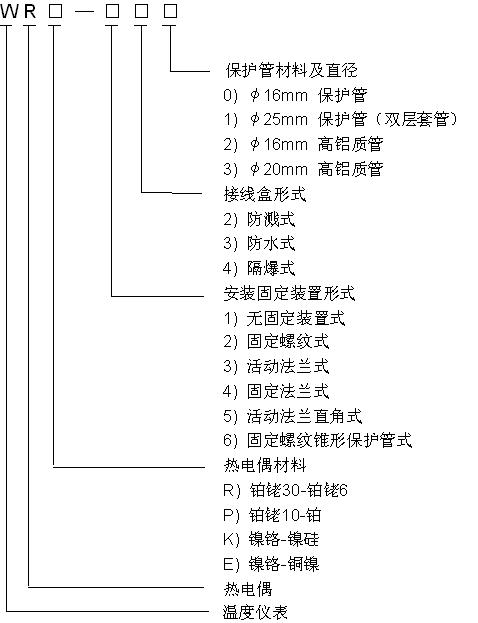

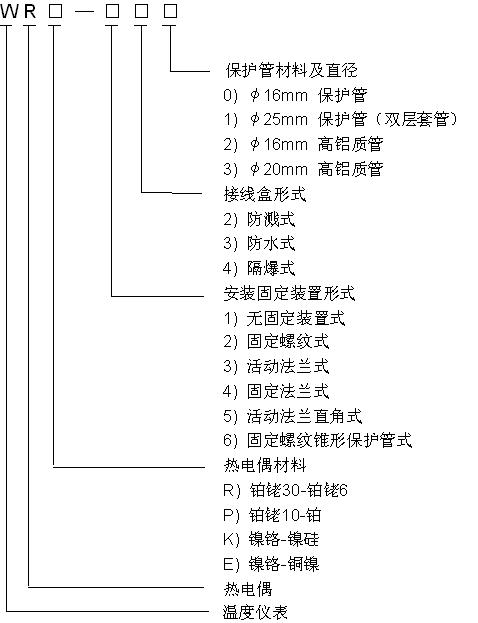

Model representation