Thermal resistance for thermal pipes

Product description:

Thermal resistance for thermal pipes

Thermal resistance in a heat pipe is measured by the resistance of a substance to changes in its temperature at the same time as its resistance changes. When the temperature gradient exists in the measured medium, the measured temperature is the average temperature in the medium of the temperature sensitive element.

The heat pipe thermal resistance as the temperature sensor, usually with temperature transmitter, controller and display instrument and other facilities, consisting of the process control system, using liquid to directly measure or control the production process in a variety of -200 to 300 DEG C range, steam and gas solids and surface temperature are widely used in petroleum, chemical. Machinery, metallurgy, electric power, textile, food and other industrial sectors, and the field of science and technology.

The thermal resistance of heat pipe mainly consists of junction box, protection tube, connection terminal, insulated porcelain column and temperature sensing element. It is composed of various fixing devices.

• imported platinum resistance (Pt100Pt1000), good consistency;

• high temperature accuracy, reliable and stable performance;

Double layer package, good vibration resistance;

High mechanical strength and good pressure resistance.

• standard pipe thread installation

Thermal resistance of a heat pipe, used as a transmitter for measuring temperature, is usually used in conjunction with display instruments, recording instruments, and electronic regulators. It can directly measure the liquid, steam and gas medium, as well as the surface temperature of the solid in various production processes.

Beijing Huaxia Risheng Technology Co. Ltd. the main production line with Pt100 platinum thermal resistance IEC international standard index number and meet the Professional Standards Division No. Cu50 copper heat resistance two assembly thermal resistance.

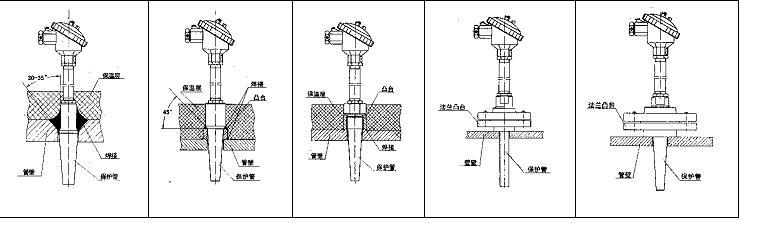

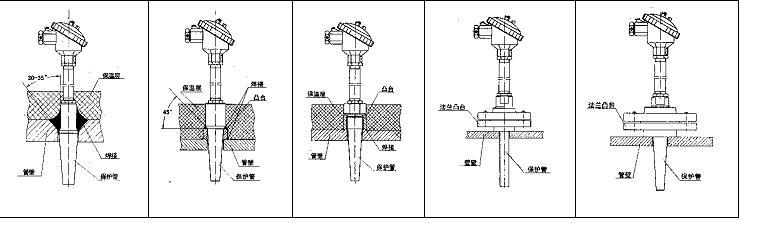

Construction of thermal resistance for thermal pipes

Thermal resistance is usually composed of temperature sensing elements, lead wires, insulating tubes, protective tubes, and junction boxes.

1. temperature sensitive components: imported film platinum resistance, Pt100Cu50 temperature sensing element.

2.: according to the type of protective tube thermal resistance, measured medium condition and measuring temperature, the protection tube made of different materials, the thermal resistance of the protection tube generally uses a variety of different grades of carbon steel, stainless steel, alloy steel and other materials.

3. junction box: junction box of thermal resistance is used for connecting the display instrument of temperature sensing element. It is made of aluminium alloy and stainless steel. It is divided into flameproof, waterproof and small splash proof structures.

4. wiring board: thermal resistance of the wiring board is generally made of ceramic, installed in the junction box, is the thermal resistance of the signal output, it is divided into single and double support type two.

5. leads: the lead is the outlet of the signal of the temperature sensing element. The lead platinum thermal resistance with silver wire made of copper thermal resistance with silver plated copper wire manufactured with thermal resistance temperature when the insertion depth of different wire diameter changes.

6. installation fixing device: thermal resistance installation fixing device for users to install fixed use, it is divided into no fixed device, fixed thread, movable flange and fixed flange and other forms.

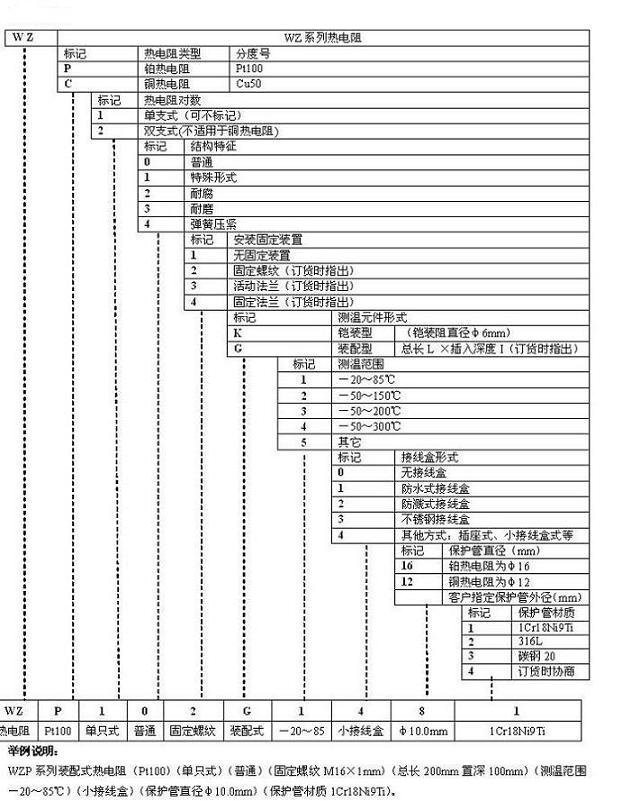

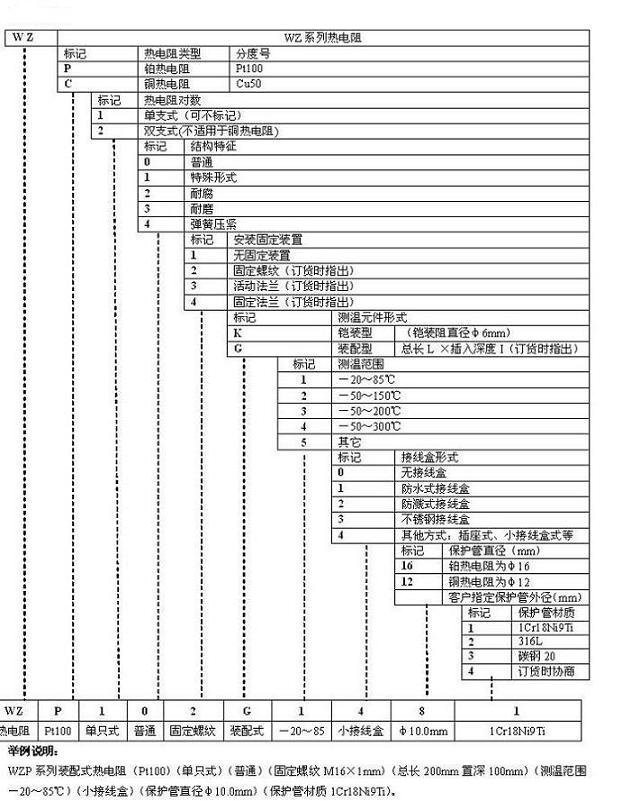

Thermal resistance type selection table for heat pipe:

Model and specification

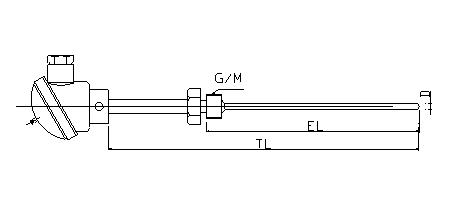

1. The basic specifications of thermal resistance for common heat pipes (mm)

Total length TL

Three hundred

Three hundred and fifty

Four hundred

Four hundred and fifty

Five hundred and fifty

Six hundred and fifty

Nine hundred

One thousand one hundred and fifty

One thousand and four hundred

One thousand six hundred and fifty

Two thousand one hundred and fifty

Deep EL

One hundred and fifty

Two hundred

Two hundred and fifty

Three hundred

Four hundred

Five hundred

Seven hundred and fifty

One thousand

One thousand two hundred and fifty

One thousand and five hundred

Two thousand

Total length TL

Two hundred and twenty-five

Two hundred and fifty

Three hundred

Three hundred and fifty

Four hundred and fifty

Five hundred and fifty

Six hundred and fifty

Nine hundred

One thousand one hundred and fifty

Deep EL

Seventy-five

One hundred

One hundred and fifty

Two hundred

Three hundred

Four hundred

Five hundred

Seven hundred and fifty

One thousand

2, other special specifications form:

Customized according to customer requirements.

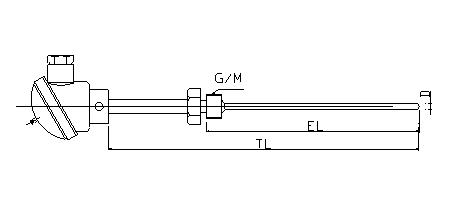

Sketch of installation structure: